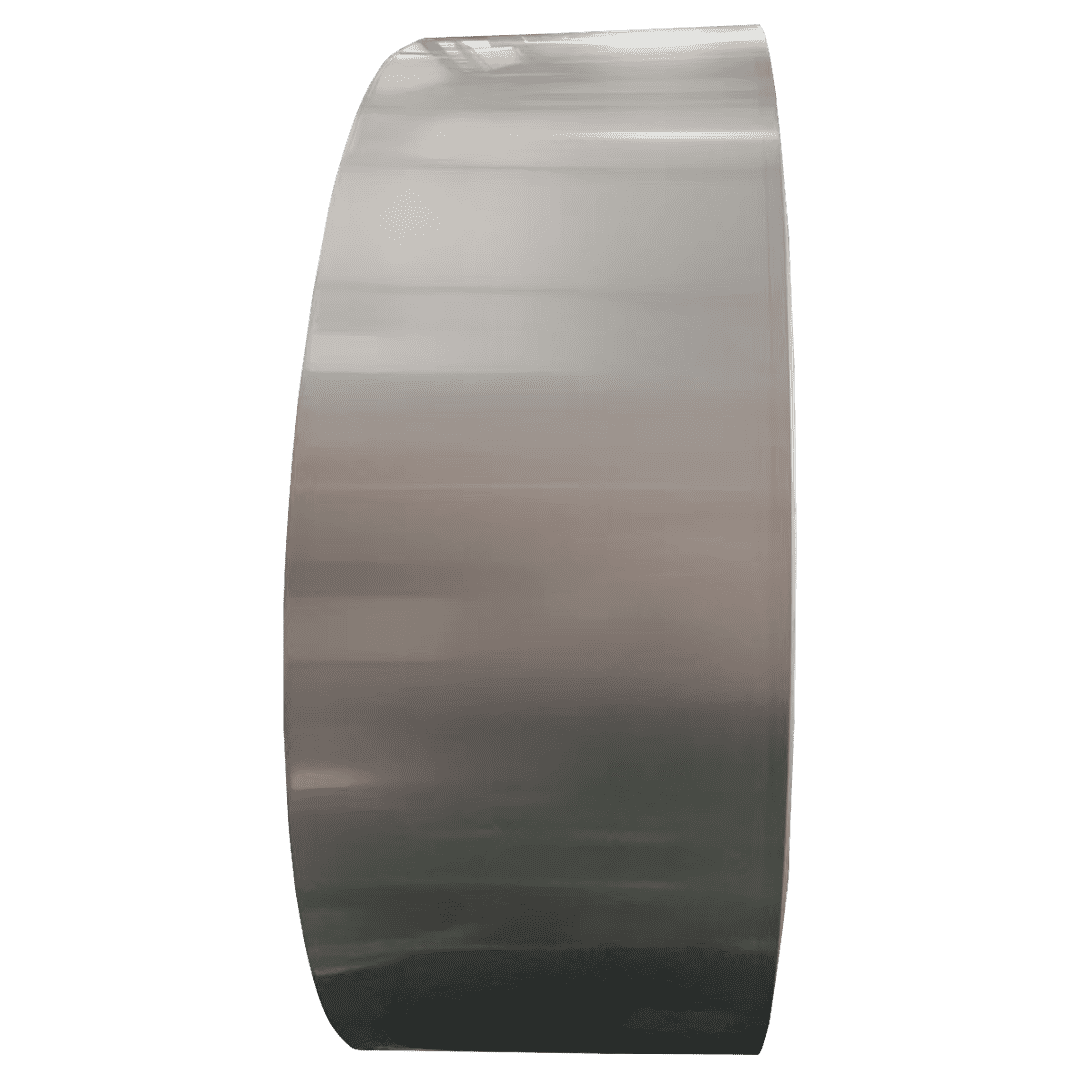

Stainless Steel Strips

Stainless steel strips are steel materials based on ordinary carbon steel, with the addition of alloying elements (chromium content >11.5 wt%). They exhibit properties such as rust resistance, color retention, and corrosion resistance. Based on microstructure, they are classified into:

- Martensitic Stainless Steel

- Ferritic Stainless Steel

- Austenitic Stainless Steel (Most widely used)

- Duplex Stainless Steel

- Precipitation-Hardening Stainless Steel

Austenitic stainless steels 301 and 304 offer excellent corrosion resistance, oxidation resistance, and good formability.

Stainless Steel Strip Grades

SUS301; SUS304; SUS316L; SUS316; SUS631

Properties

High elasticity, superior corrosion resistance, and excellent formability.

Applications

Food/medical equipment, communication connectors, new energy battery components, etc.

Chemical Composition Tables

Table 1: Austenitic & Martensitic Grades

| Grade | C | Ni | Cr | Fe | S | P | Si | Mn | Mo |

| SUS301 | 0.15 | 6.0-8.0 | 16-18 | Bal. | ≤0.03 | ≤0.045 | ≤1.0 | ≤2.00 | – |

| SUS304 | 0.08 | 8.0-10.5 | 18-20 | Bal. | ≤0.03 | ≤0.045 | ≤1.0 | ≤2.00 | – |

| SUS316L | 0.03 | 12-15 | 18-20 | Bal. | ≤0.03 | ≤0.045 | ≤1.0 | ≤2.00 | 2-3 |

Table 2: Precipitation-Hardening & Ferritic Grades

| Grade | C | Ni | Cr | Fe | S | P | Si | Mn | Al |

| SUS631 | 0.09 | 6.5-7.75 | 16-18 | Bal. | ≤0.03 | ≤0.045 | ≤1.0 | ≤2.00 | 0.75-1.5 |

|

Reviews

Clear filtersThere are no reviews yet.